FRP Tanks | Brine Water Tanks

Located in the heart of

Located in the heart of

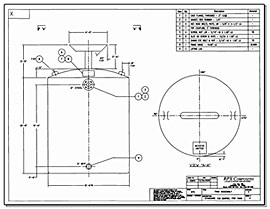

We offer a full line of tanks ranging in size from 5 BBL to 500 BBL in diameters from 5’ to 12’ and can recommend specific resin systems to meet your application needs. We offer an economical line of standard FRP tanks with commonly required fittings and features used in the gas and oil fields. However RPX is happy to provide you with customized fittings and features to meet your specific requirements. Our design team has more than 30 years of oil and gas industry experience.

|

Fiberglass Reinforced Plastic (FRP) has been used for various types of equipment since early 1950. The strength and corrosion resistance of FRP tanks is unmatched by steel or other poly tanks. At RPX Composites, we incorporate premium resins and materials with quality controlled manufacturing to produce superior tanks. |

|

Consider the other benefits of a

|

|

|

Economical - Fiberglass brine storage tanks offer considerable dollar savings when compared to steel tanks and many poly tanks. Our fiberglass tanks weigh approximately 60% less than steel tanks. Installation is easier and more flexible than poly tanks, which can save money in the long run. Also our fiberglass tanks save money because they are more durable and have a longer service life than steel tanks and similar polytanks. |

|

|

Construction & Tank Features – Our tanks meet industry accepted standards including ASTM D 3299, ASTM D 4097 and of course Customer’s specifications. We are able to offer our customers the following:

|

|

Customization – Above all RPX wants to make sure our tanks meet your specific requirements.

|

|